10000 IPH RO PLANT Specification

- Efficiency (%)

- efficiency ranging from 60% to 75% in terms of water recovery rate, meaning it converts that percentage of the feed water into purified wate

- Power Consumption

- 220 Volt (V)

- Technology

- The core technology involves using a semi-permeable membrane to filter out contaminants and dissolved solids. Different components and configurations contribute to the overall system, including the type of membrane, pump, and pre

- Water in conductivity

- A 10,000 liters per hour (LPH) RO (Reverse Osmosis) plant's output water conductivity will be very low, ideally close to zero or very close to zero. This is because RO technology is designed to remove dissolved solids, including salts, which are the primary contributors to water conductivity.

- Usage & Applications

- a high-capacity water purification system widely used in various industrial and commercial applications. These plants are designed to remove impurities, dissolved salts, and contaminants from water sources, providing clean and purified water for diverse needs.

- Pump Type

- A 10000 liters per hour (LPH) RO plant typically uses a high-pressure multi-stage pump. These pumps are essential for creating the pressure needed to force water through the reverse osmosis membranes, which remove impurities.

- Feature

- a high recovery rate (typically up to 70%), and various monitoring and control systems for efficient operation.

- Water Out Conductivity

- A 10,000 liters per hour (LPH) RO (Reverse Osmosis) plant is designed to significantly reduce the conductivity of water, ideally to near zero or very low levels. The conductivity of RO water is a key indicator of its purity, as it measures the

- Water Source

- Ground Water

- Power Source

- 3-Phase, 440V, 50Hz

- Product Type

- standard, enhanced with UV/UF, with mineral addition, and customized options.

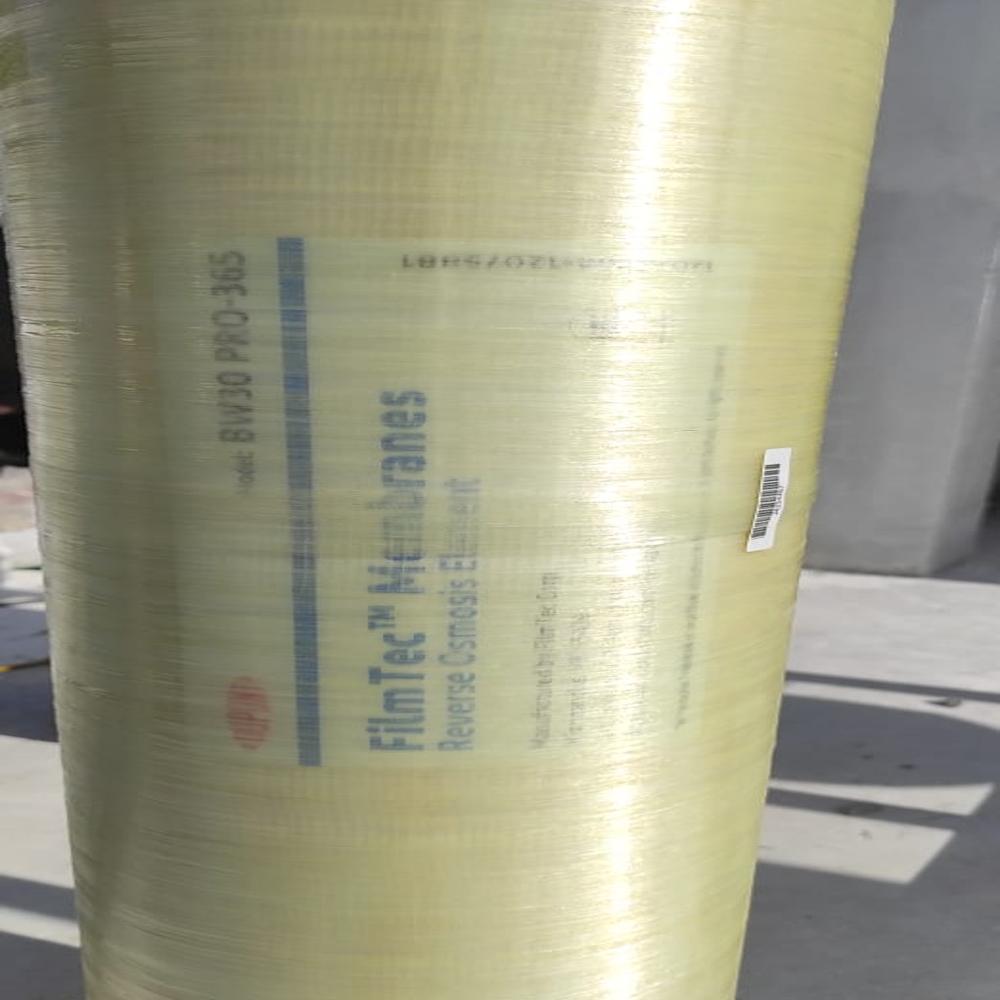

- Material

- Stainless Steel (SS) and FRP (Fiber Reinforced Polymer). These materials are chosen for their durability, corrosion resistance, and ability to withstand the pressures and conditions of the reverse osmosis

- Automatic Grade

- Full Automatic

- Filter Type

- pre-filters like sand and activated carbon filters, followed by a reverse osmosis (RO) membrane and potentially post-filters such as UV sterilizers or UF (ultrafiltration) membranes.

- Installation Type

- Prefabricated

10000 IPH RO PLANT Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2 Per Month

- Packaging Details

- NUMBAR OF 1

- Main Export Market(s)

- Asia

- Main Domestic Market

- South India

About 10000 IPH RO PLANT

10000 LPH RO PLANT REVERSE OSM0SIS RO WATER PURIFICATION AND DESIGNED INDUSTRIAL OR COMMERCIAL USE AS PRE FILTRATION STAGES POST TREATMENT LIKE UV OR OZONE STERILIZATION AUTO MATOMATIC FEATURES FOR EFFICIENT OPERATION THESE PLANT ARE BUILT WITH STAINLESS STEEL A 10,000 liters per hour (LPH) Reverse Osmosis (RO) plant typically includes a raw water pump, sand filter, activated carbon filter, micron filter, high-pressure pump, RO membranes, and a pure water tank. It may also incorporate an ozone or UV system for post-treatment. The plant is designed to remove suspended solids, chemicals, and microbes, producing purified water for various applicatio